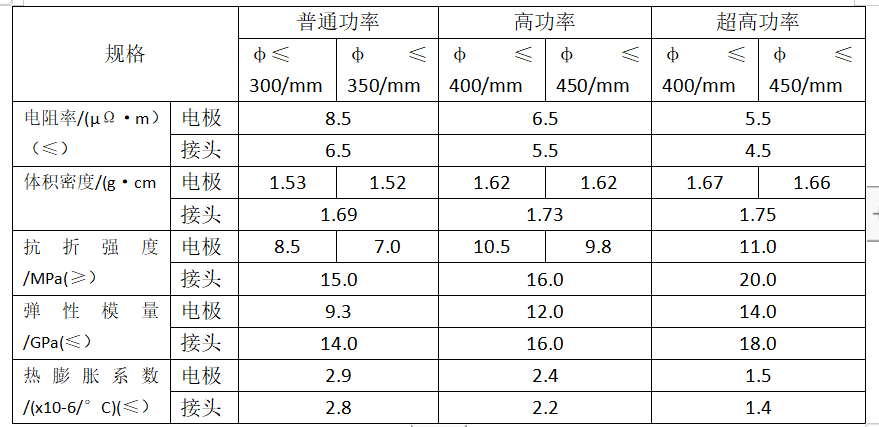

Quality index of graphite electrode

Resistivity is a parameter used to measure the conductivity of the electrode, which refers to a property of the conductor's resistance to the current when the current passes through the conductor. The value is equal to the resistance value of the conductor with a length of 1m and a cross-sectional area of 1m² at a fixed temperature, in µΩ·m. The lower the resistivity, the better the electrode conducts electricity in use, and the lower the consumption. The way to reduce the resistivity is to use high-quality raw materials, increase the bulk density of the product, and increase the graphitization temperature.

Bulk density is the ratio of the mass of the graphite electrode sample to its volume, in g/cm³, body temperature, etc. The higher the density, the denser the electrode, and the strength and antioxidant properties are positively correlated, in general. The higher the volume density of the same kind of electrode, the lower the resistivity.

The way to increase the volume density is to adjust the formula, increase the amount of small grain and powder, use raw materials with high true density, use asphalt with high coking value and increase the number of impregnation.

Flexural strength is a parameter that characterizes the mechanical properties of graphite materials, also known as flexural strength, which refers to the ultimate resistance of bending to breaking moment after external force is perpendicular to the axis of the object, and the unit is MPa. The strength of graphite materials is significantly different from that of other metals and non-metals, and its strength increases with the increase of temperature, reaching the highest strength at 2 000-2 500 sinks, and 1.8-2 times the force concentration, and then decreasing. The higher the strength of the electrode, the joint is easy to break in use.

The ways to improve the bending strength are to reduce the particle size of carbon in the formula, increase the bulk density of the product and reduce the internal defects of the product.

Elastic modulus is an important aspect of mechanical properties, an important aspect of measuring the elastic deformation ability of materials, and an index to measure the elastic deformation ability of materials, referring to the ratio of stress and strain in the elastic deformation range of materials, the unit is CPa. The greater the elastic dispersion, the greater the stress required to produce a certain elastic deformation, in simple terms, the greater the elastic modulus, the more brittle the material. The smaller the elastic modulus, the softer the material.

The level of elastic modulus plays a comprehensive role in the use of electrodes. The bulk density of the product is large, the denser the electrode is, the greater the elastic modulus is, but the worse the thermal vibration resistance of the product is, the more likely it is to break off. In the production, often through the adjustment of the formula grain size, the product volume density of high and low palm to adapt to the use of the elastic modulus value.

The coefficient of thermal expansion refers to the measure of the expansion degree of the material after being heated, that is, when the temperature rises by 1C, the proportional constant of the expansion of the solid material sample in a certain direction is called the linear expansion coefficient along the direction, the unit is 1x10/C. If not specifically indicated, the coefficient of thermal expansion refers to the coefficient of linear expansion, the axial and radial linear expansion coefficient of graphite electrode is very different, the radial linear expansion coefficient is 0.8 to 1 times larger than the axial linear expansion coefficient, the thermal expansion coefficient of graphite electrode quality index refers to the coefficient of axial thermal expansion.

Previous: calcined coal carburizer - CAC